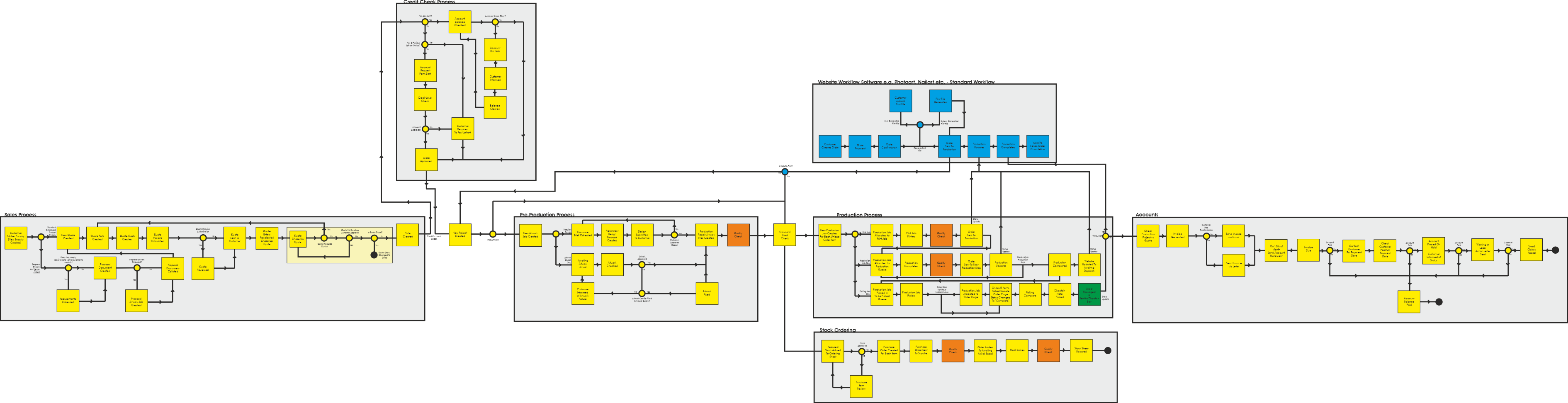

8.5 Production & Service Provision

Control of Production and Service Provision

Vector Graphic Version Click Here

MaticTrack

The MaticTrack is Matic Media Services Limited internal inhouse developed Enterprise Resource Management software. It tracks all aspects of customer, order and production management. At last update it maintained...

- Customer Information

- Company Details

- Contact Details

- Sales

- QuickQuotes

- Quotes

- Carts

- Orders

- Payments

- Artwork

- Catalogue

- Customer Price Lists

- Operations

- Projects

- Jobs

- Endpoints

- Dispatch

- Stock

- Job Planning

- Plant & Building Maintenance

- Purchasing

- Remittances

- Purchase Orders

- Suppliers

- Accounts

- Invoicing

- Credits

- Journals

- Marketing

- Marketing Lists

- Third Party Systems Integration

- Graphic Warehouse Website

- CMS

- Ecommerce

- Blog

Validation of Processes for Production and Service Provision

- Operators will carry out their duties as per the Job Pack which are issued by the Operations Manager.

- All operators sign the Job Pack on completion of their specific task before the job proceeds to the next part of the process.

- The operators signature signifies that in-process inspection has taken place.

- Maintenance records are updated at the required intervals to ensure that maintenance checks on plant equipment are being carried out.

Identification and Traceability

- All orders accepted by the Company are allocated a job number which is unique to that particular order. This is made up of a prefix representing the order source and a unique tracking number ending with a version control number.

- QUO:12345:01

- Source: Quote

- Identification Number: Quote 12345

- Version Number: 01

- WEB:12345:01

- Source: Web Order

- Identification Number: Order 12345

- Version Number: 01

- QUO:12345:01

- Redo of external non conformance numbers are tracked with a prefix of RED e.g.

- RED:WEB:12345:01

- Invoices Identification is automatically assigned based on the order id e.g.

- If order is WEB:12345, the invoice id will be WEB:12345

- Duplicate invoices numbers are not allowed therefore duplicate invoicing is impossible

- A Project is allocated to each order with details which correspond to customer requirements.

- A Project has many Jobs

- A Project as many Endpoints

- A Job has many Artworks

- A Job represents a list of production processes and the current production process that is active

- Each operator completes the Job process step on completion of his area of responsibility.

- This completion represents a quality control check.

- An operator cannot complete a process without having completed training in that process for QA

- Any product which is rejected, for any reason, will have a rejected self-adhesive sticker attached and placed in a quarantine area of the factory.

- All Job Bags are held digitally for a minimum of 2 years.

- The current test status and test and inspection results are detailed on the Job including final inspection, this is stored are logs digitally on MaticTrack.

Stock Control & Storage

- Stock is held and controlled as per supplier data sheets depending on the product.

- Stock is identified, where needed labelled and grouped as per its type.

- Stock is organised into three types

| Type | Descriptor |

| In Use | Is currently in use, held in either lamination room or print room |

| Partial Use Stock / Offcuts | Is partially used and is held as stock held, held in Kanban System on Mezzanine or in sheet media racks in Stock Bay |

| Stockheld | Unopened roll stock held in Roll Media racks in Stock Bay |

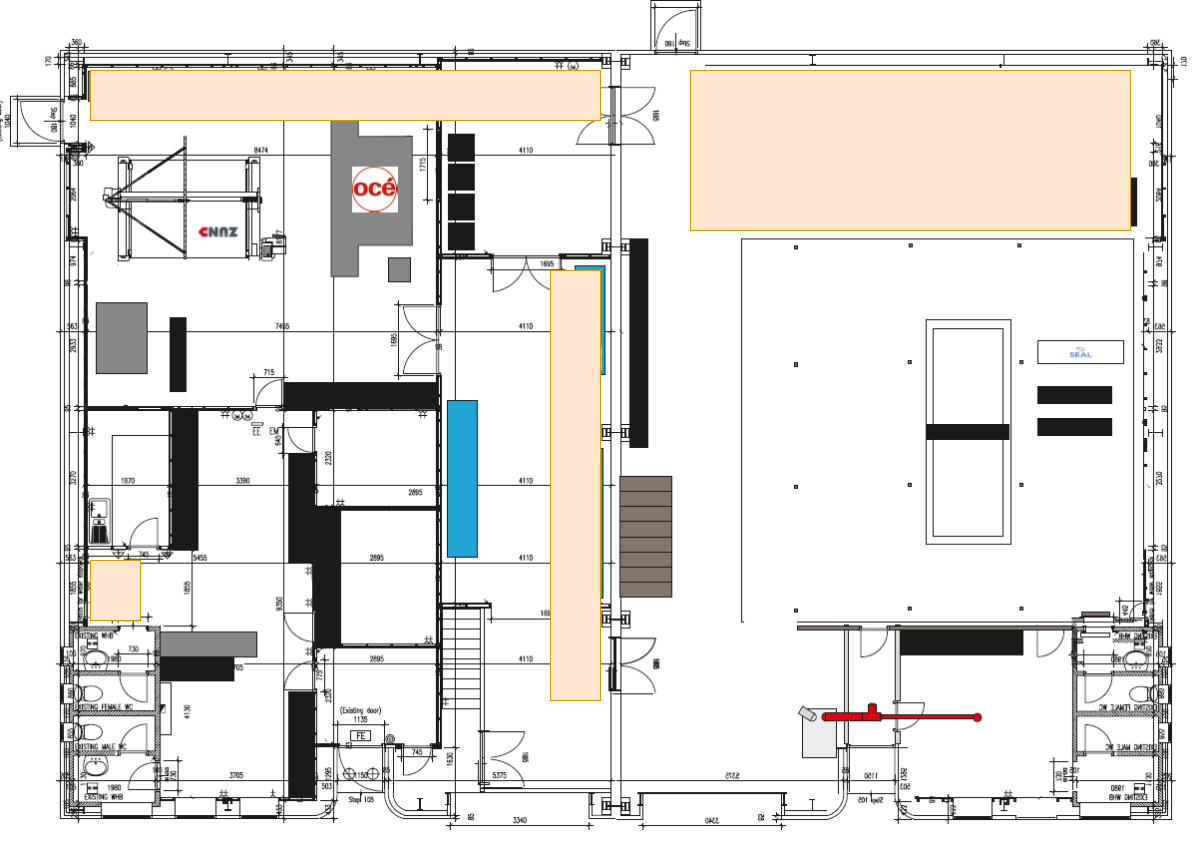

Stock Storage Zones

Stock Imagery

In Use Stock

Partial Use Stock / Offcuts

Stock Identification

Stockheld

No Comments