Health & Safety

UV Ink and Flush

Introduction

The safety concerns involved with the handling and use of the UV ink and Flush are detailed in the Material Safety Data Sheet (MSDS) documents. Review them before handling any UV ink or flush.

CAUTION

UV inks can be harmful if not properly handled. Follow the MSDS guidelines carefully in order to ensure maximum safety. The information below is a summary of the MSDS documents published by the UV ink manufacturer

Health and Safety Equipment

TDLR;

- Wear nitrile gloves

- Wear protective safety googles when handling raw inks

- Only wear nitrile gloves for a maximum of 10 minutes

- Dispose of contaminated nitrile gloves in a contained method

- If you get ink on your hands, wash immediate with mild soap and water

- DO NOT USE ALCOHOL TO CLEAN HANDS

The operator must wear nitrile gloves and safety glasses with side shields when handling inks. Read and practice safety guidelines as outlined in the MSDS for each ink. Post these documents in the work area as required by prevailing law. MSDS are provided with all inks and flush when you purchase them.

Chemicals in UV ink begin to permeate nitrile gloves in less than 10 minutes. While this actionmay not be visible, changing contaminated gloves should occur every few minutes. These penetrating chemicals have no pigment so they are not visible; therefore just because you don’t have pigment on the glove or your skin doesn’t mean that exposure has not occurred.

Latex gloves may appear to be robust but provide no protection at all. They only temporarily stop UV pigment penetration while allowing the invisible harmful chemicals to pass through, where they are trapped next to the skin, improving contact and associated risk. Océ recommends that only nitrile gloves, which have been checked for chemical resistance and approved by the Océ Occupational Health and Safety department, are used. At present, this includes only the Ansell Touch N Tuff gloves, 92-600 for smooth or 92-605 for textured. Use the gloves one time only, and replace them immediately if they are punctured or degraded. Never reuse contaminated gloves once they are removed.

CAUTION

Always use Nitrile gloves when working with UV curing inks. If you get ink on your skin, wash it off with mild soap and water. Never use alcohol to remove UV ink from your skin as this will transport the chemicals more easily through your skin and into your body. Hands should be inspected on a regular basis for any signs of skin damage or inflammation.

UV Lamps / UV Curing System

UV-curable ink need a high energy level of UV light to cure. The UV curing system is made up of two mercury arc lamps attached to the carriage.

TLDR;

- The UV Lamps get very hot, take care when handling

- The UV Lamps contain mercury, take proper precautions if a lamp breaks

- Do not directly look at the UV lamp system when curing

- Keep a distance of more than 1 meter when the UV lamps are printing

- Make sure your working area is well ventilated when the UV lamps are operating

How to Handle UV Lamp: UV lamps operate at high temperatures. Never touch a lamp in operation. Let the lamps cool for a minimum of five minutes before attempting any maintenance. Use extreme care in handling the UV lamp bulbs. The UV bulbs contain a small amount of metallic mercury which is toxic when ingested, handled, or breathed. Therefore, if bulbs are broken, care should be taken to clean up the spill immediately, and then disposed of according to local regulations concerning Mercury disposal.

Bare skin contact with the UV lamp bulbs must be avoided. When heated, compounds from the skin can form permanent etching on the surface of the UV bulb. A contaminated bulb may fail prematurely.

Ozone: As a UV lamp warms up, it briefly passes through a section of the light spectrum which excites oxygen molecules enough to create ozone. Once a UV lamp has completely warmed up, only very minute amounts of ozone are present.

Situational Awareness

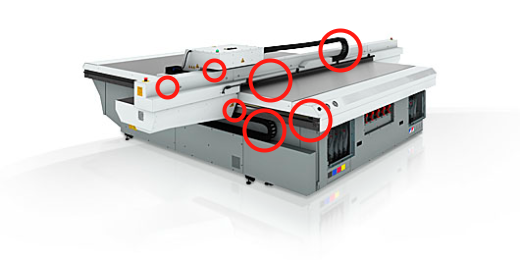

The highlighted areas below should be avoided when the machine is operating as they offer a risk of CRUSH injuries.

Full examples of crush areas are available on pages 27 to 30 of the Arizona Manual from Oce.

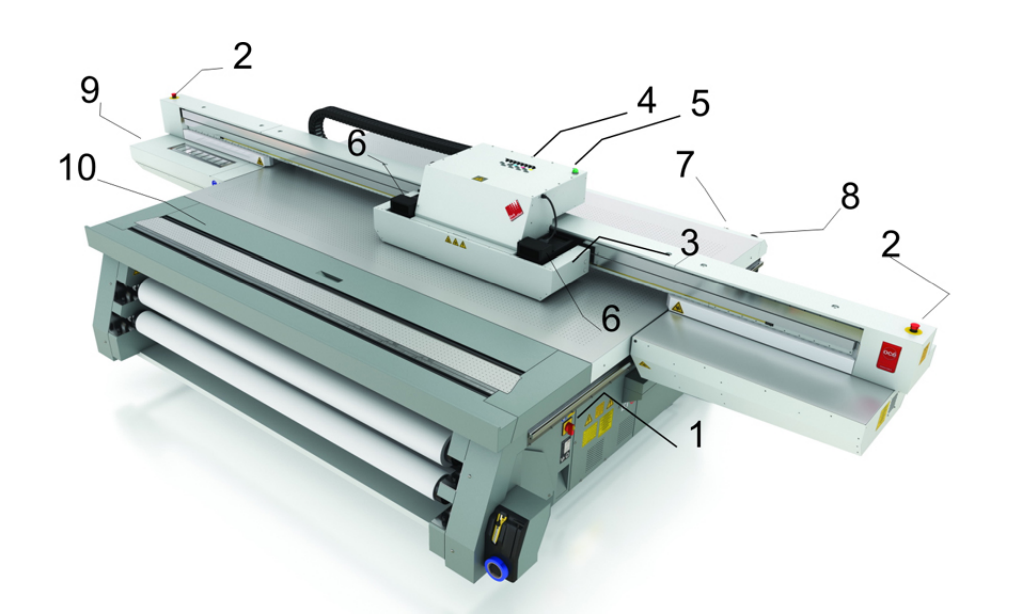

Emergency Stop Buttons

There are 3 emergency stop buttons located on the printer. Two on each end of the gantry and one on the work station.

You can see the two buttons on the gantry in the picture below. Highlighted as item 2.

No Comments